With DRYLET AWARD WINNING BIOCATALYST

What makes our Ultra-Oxygen DRYLET BIOCATALYST so special?

The UO2-Drylet biocatalyst is renowned for its award-winning status. Complemented by our advanced Ultra-Oxygen Micro and Ultrafine Bubble generators, these cutting-edge technologies redefine wastewater treatment, ushering in elevated bioremediation, microbial protection, and oxygenation. This powerful collaboration empowers wastewater treatment operators and facilities to enhance operational efficiency and environmental impact.

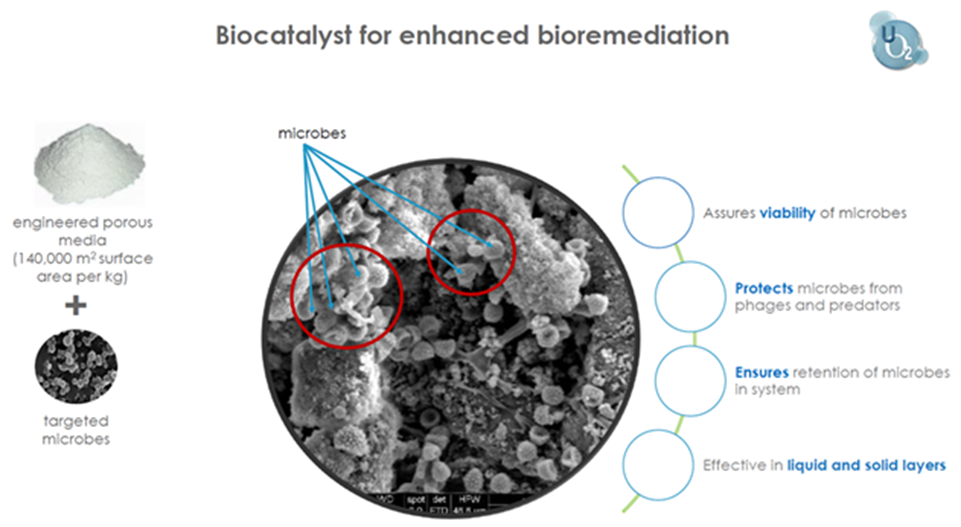

The UO2-Drylet biocatalyst stands as a pioneer in enhanced bioremediation, securing microbe viability through its patented silica substrate that safeguards against phages and predators, ensuring sustained efficacy in both liquid and solid layers. The retention of these microbes within the system paves the way for unparalleled results.

Reach out to us for comprehensive product insights on AQUA-ASSIST, BIO-REACT, and MANURE MAGIC, and discover how this integrated solution transforms possibilities in waste management, agriculture, and beyond.

Revolutionizing Wastewater Treatment

Unleashing the Potential of Nature to Transform Wastewater Treatment

Introduction:

In the quest for sustainable and efficient wastewater treatment solutions, a ground-breaking product has emerged to revolutionize the industry. DRYLET microbial consortia biocatalyst is now available, thanks to an exclusive partnership with Soldevco Pty Ltd. This innovative technology harnesses the power of microbial consortia, providing unmatched advantages over traditional enzyme-based treatments. Let us explore why DRYLET is poised to transform wastewater treatment in the world.

Enhanced Efficiency and Surface Area:

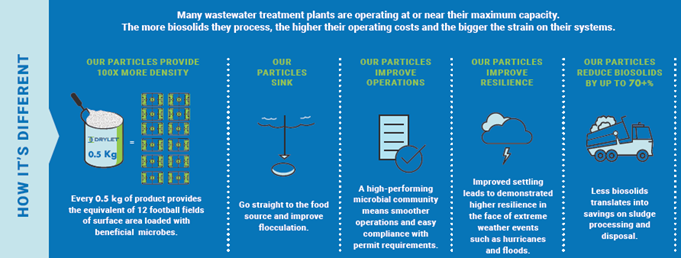

Imagine unlocking the hidden potential of your wastewater treatment process. With DRYLET, microbes gain unprecedented access to food sources, thanks to its enhanced sorption capacity. A mere 1kg of DRYLET product boasts a surface area equal to a staggering 22 rugby fields. This means that microbes can efficiently access and utilize nutrients, accelerating the treatment process and maximizing biodegradability.

Superior Microbe Protection:

DRYLET’s patented product features an ingenious armour coating of silica dioxide. This protective shield not only safeguards the microbes from hostile microbes and chemicals but also prevents viral diseases and predation. By providing a safe haven for the microbial consortia, DRYLET ensures that they arrive ready to work their magic, promoting a robust and thriving microbial ecosystem.

Optimized Zone Delivery and Extended Retention Time:

The meticulous design of DRYLET’s silica substrate ensures optimal zone delivery and extends the retention time of the microbial consortia. This means that the biocatalyst remains active in the treatment system for an extended period, continually enhancing microbial activity and performance. The result is a highly efficient and effective treatment process.

Unleashing the Power of Biocatalysts:

DRYLET’s biocatalysts unlock a range of remarkable benefits for wastewater treatment. They enhance cellular lysis and accelerate cell rupture, promoting efficient substrate release. Additionally, DRYLET boosts the cleavage of light-cell-mass (LCM), further increasing biodegradability. Furthermore, particulate BOD is solubilized, enabling the treatment system to address even the most challenging wastewater constituents.

Non-Destructive, In-Situ Lysis:

In the pursuit of eco-friendly solutions, DRYLET offers a game-changing advantage with its in-situ, non-destructive lysis. Unlike traditional methods that may harm the microbial community, DRYLET’s biocatalysts enable controlled cellular lysis without compromising the overall ecosystem. This ensures the long-term sustainability and balance of the treatment process.

A Cost-Effective, Nature-Driven Solution:

DRYLET is a food-grade product that requires zero capital expenditure (capex). By leveraging the power of nature and enhancing microbial activity, DRYLET significantly increases capital recovery. This translates into substantial cost savings, making it an economically viable choice for wastewater treatment facilities of all sizes.

DRYLET Microbial Consortia Biocatalyst and Ultra-Oxygen Technology for Unparalleled Wastewater Treatment

UO2-DRYLET – Biocatalyst innovation

At the heart of the Ultra-Oxygen Water Quality Division beats an unwavering commitment to innovation and transformation. Soldevco (Pty) Ltd has ingeniously sculpted a future where water quality isn’t just maintained; it’s elevated to an art form. At the epicentre of this visionary endeavour stand the Micro and Ultrafine Bubble Generators – marvels of technology that infuse the essence of life, oxygen, into every droplet, redefining the very essence of purity.

But the essence of innovation doesn’t stop there. Enter the UO2-Drylet Biocatalyst Innovation, a symphony of science and nature, revolutionizing how we harmonize with our environment.

The face of water quality optimization is being transformed, and it wears the glow of inspiration. Soldevco’s Ultra-Oxygen Water Quality Division isn’t merely delivering products; it’s pioneering a movement that celebrates the elegance of purity, the brilliance of innovation, and the sanctity of nature. In these creations, we see the ripple effects of change – a change that heralds a future where water, that life-affirming elixir, flows clearer, healthier, and more abundant than ever before.

Revolutionizing the Wastewater Industry with the Perfect Pairing

Introduction:

South Africa’s wastewater industry is on the verge of a ground-breaking transformation. In an exclusive partnership with Soldevco Pty Ltd, DRYLET microbial consortia biocatalyst is now available for the first time in the region. By harnessing the incredible potential of microbial consortia and complementing it with Ultra-Oxygen micro and ultrafine bubble-generating technology, a new era of wastewater treatment is here. Let’s explore why this powerful pairing is set to redefine the standards of efficiency and environmental stewardship in South Africa.

Unmatched Microbial Performance:

When DRYLET’s microbial consortia biocatalyst and Ultra-Oxygen technology join forces, the results are unparalleled. The microbial consortia, armed with DRYLET’s sorption capacity and protective silica armour, work synergistically with the oxygen-rich micro and ultrafine bubbles to create an environment conducive to exceptional microbial performance. The increased dissolved oxygen levels promote enhanced aerobic conditions, supporting the growth and activity of beneficial microorganisms.

Optimized Treatment Efficiency:

By combining DRYLET’s biocatalysts with Ultra-Oxygen technology, wastewater treatment plants can achieve unparalleled treatment efficiency. The heightened oxygen levels improve the breakdown of organic matter, ensuring faster and more thorough degradation. This optimized efficiency translates into reduced treatment time, enhanced pollutant removal, and increased overall treatment capacity.

Superior Nutrient Uptake:

One of the key advantages of this pairing is the improved nutrient uptake by microbial consortia. The elevated dissolved oxygen levels facilitated by Ultra-Oxygen technology enable microorganisms to efficiently utilize available nutrients, promoting robust growth and metabolism. As a result, the microbial consortia in DRYLET thrive, effectively removing organic compounds and pollutants from the wastewater.

Enhanced Cell Resilience:

The combination of DRYLET microbial consortia and Ultra-Oxygen technology provides an additional layer of protection for the microbial community. The oxygen-rich micro and ultrafine bubbles help fortify the microbial cells, boosting their resilience to adverse conditions and potential stressors. This resilience ensures the long-term stability and effectiveness of the treatment process, even in challenging wastewater compositions.

Improved Energy Efficiency:

The incorporation of Ultra-Oxygen technology into the treatment process brings about notable energy savings. By providing a highly efficient method for oxygenation, the technology reduces the reliance on energy-intensive mechanical aeration systems. This translates into lower energy consumption, decreased operational costs, and a more sustainable approach to wastewater treatment.

Environmental Sustainability:

The synergistic effects of DRYLET microbial consortia and Ultra-Oxygen technology align perfectly with South Africa’s commitment to environmental sustainability. The enhanced treatment efficiency and reduced energy consumption contribute to lower carbon emissions and a smaller ecological footprint. By embracing this powerful pairing, wastewater treatment facilities can actively contribute to a greener, cleaner future for South Africa.

Conclusion:

The union of DRYLET microbial consortia biocatalyst and Ultra-Oxygen micro and ultrafine bubble-generating technology heralds a new era of wastewater treatment excellence in South Africa. This perfect pairing harnesses the collective power of microbial consortia and oxygenation, optimizing treatment efficiency, nutrient uptake, and cell resilience. With reduced energy consumption and a steadfast commitment to environmental sustainability, this dynamic duo sets a new standard in wastewater treatment. Don’t miss the opportunity to revolutionize your wastewater treatment process. Contact Soldevco Pty Ltd today and embrace this transformative synergy for a brighter, more sustainable South Africa.

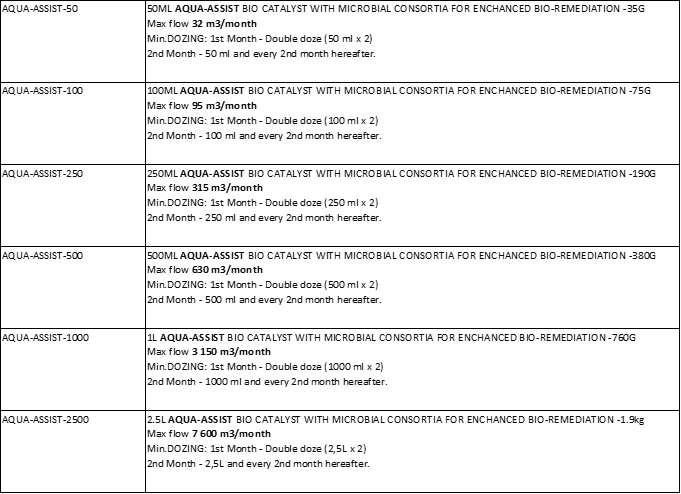

AVAILABLE PRODUCTS

The Technology

Dryletʼs innovative biocatalyst draws from material science and microbiology. The products are comprised of carefully selected beneficial microbes embedded inside non-toxic particles made of an engineered porous media substrate. The particles are approximately 200-600 μm in size. They protect the microbes, allowing them to thrive and replicate fast so they can be effectively integrated into microbial ecosystems. The product can be applied during all seasons. Microbe activity will be higher during warmer temperatures but will also be effective in colder conditions.

- Microorganism counts >> 200 billion cfu/g ,

- Dry to the touch,

- White to a light brown free-flowing powder

Support

Applying the product on large-scale projects would require assistance and the development of an application methodology and execution plan. Free support is provided on large projects and includes a detailed cost analysis and dosing plan for 2 years.

Handling, Storage and shelving life.

- Shelf life is 5 years when stored in a cool dry place. Do not store more than 48ºC for extended periods.

- Prevent the formation of dust. Any deposit of dust which cannot be avoided must be regularly removed. Use only in well-ventilated areas.

- Keep containers tightly sealed. Protect from humidity and water.

- Impermeable gloves are advised for repeated or prolonged contact.

Hazard(s) identification

The products are not classified as hazardous according to the Globally Harmonized System (GHS).

Safety Data Sheet according to OSHA HCS (29 CFR 1910.1200) and WHMIS 2015 regulations available on request.

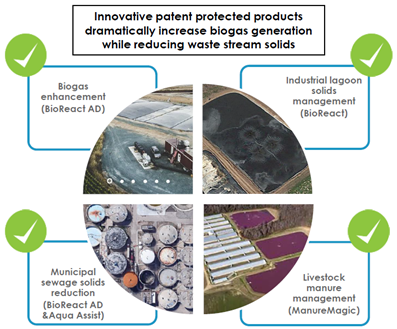

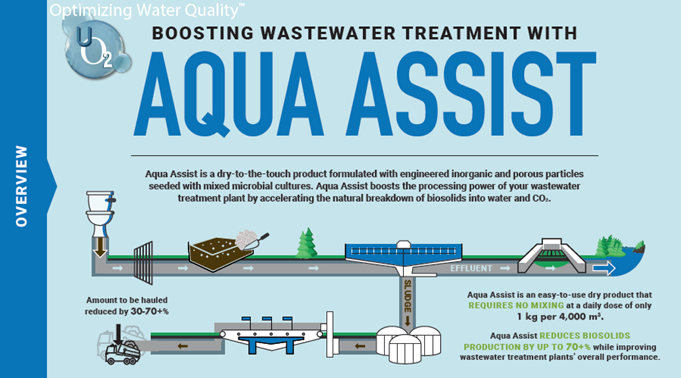

AQUA-ASSIST

AQUA-ASSIST biocatalyst with microbial consortia for enhanced bioremediation in AERATED basins.

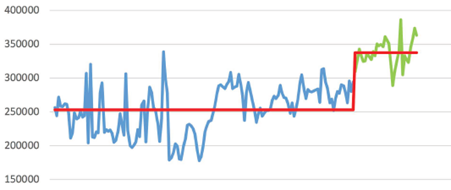

Case studies of a 15,000-m3/day and a 19,000-m3/day WWTP are available and will show sludge reductions between 24% and 41%, and significant savings in operating costs.

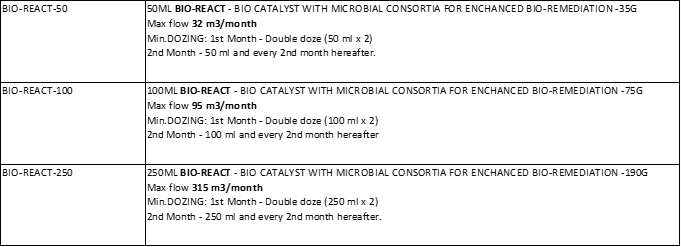

BIO-REACT & MANURE MAGIC

BIO REACT & MANURE MAGIC biocatalyst with microbial consortia for enhanced bioremediation in ANAERATED basins.

Bio React Drain is a dry-to-the-touch powder specifically formulated with patented Micro Bioreactor (MBR) particles. These benign particles are loaded with mixed microbial cultures that have been specially selected to remediate commercial kitchens and restaurant environments, including clogged floor and sink drains.

Because it can solve some of the most difficult grease and grease trap issues, Bio React Drain can significantly reduce odour in drains and will save users the costs associated with regular hydro jet services. Containing no chemical ingredients and no genetically modified organisms, Bio React Drain delivers all these benefits without any adverse impact on the environment.

HOW DOES BIO REACT WORK?

Protected in the particles, beneficial bacteria reproduce at significantly accelerated rates, consuming solids and foam, thus reducing odour and gas build-up.

ADVANTAGES OVER LIQUID TREATMENTS

• >100x higher microbial counts over liquid bioremediation products

• Requires no premixing

• Adheres to solids in water

• Delivers millions of micro bioreactors (MBR), which contain billions of microbes, directly to the fat, oil, and grease layer.

• MBR embed in fat, oil and grease layer and produces millions of additional colonies that keep the sludge liquified.

• Ease of use and long shelf life

• Ease of transportation in dry form

• Safe for pipes and plumbing

DO NOT USE HOT WATER

Bio-React also enables the enhanced degradation of undigested solid waste (hydrolysis), increasing BIOGAS GENERATION and solids reduction.

The application protocol is tailored to each facility, after analysis of influent characteristics and of historical performance average data.

A daily dose of 0.5 to 1 kilogram is typically recommended per 3 800 daily cubic meters of wastewater flow treated at the plant.

It is possible to achieve >300% biogas generation boost, and up to a 49.2% Total Solids reduction.

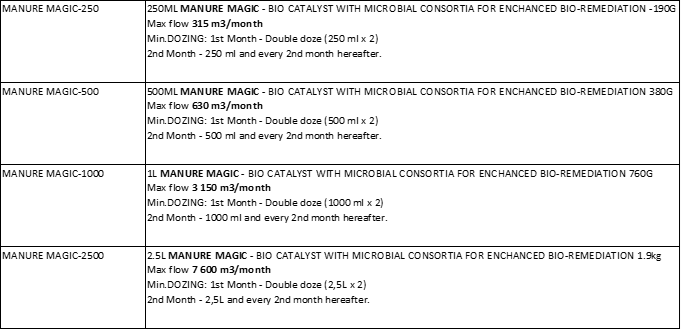

WHAT IS MANURE MAGIC?

ManureMagic is a dry-to-the-touch powder formulated with patented Micro Bioreactor (MBR) particles loaded with mixed microbial cultures that turbo-charge the natural process of anaerobic digestion in pits and lagoons. Every kilogram of the product provides about 14 hectares of area covered with billions of beneficial microbes. Drylet’s MBR particles provide bacteria with an ideal environment to reproduce at significantly accelerated rates, consuming and converting organic waste directly to gas and water.

ManureMagic® is organic, highly concentrated and utilizes millions of nano bioreactors to deliver hundreds of billions of curated microorganisms that consume solids associated with animal production. In addition to reducing nuisance issues such as solids, odour, crust formation, and gas/foam build up, ManureMagic has been proven to improve animal feed efficiency, producing a healthier animal, at a higher weight, in less time. It can also increase the barn survival rate resulting in higher incremental revenue per animal.

ManureMagic also reduces hydrogen sulphide and odours up to 40% and 50% respectively.

SUPERIOR PRODUCT ADVANTAGES

General

The benefits of DRYLET microbial consortia, such as their broad enzymatic activity spectrum, adaptability, enhanced treatment efficiency, and potential for self-regulation, provide advantages over enzymes, which offer specific enzymatic activities and controlled application.

By harnessing the collective enzymatic capabilities and adaptability of microbial consortia, wastewater treatment systems can effectively degrade a wide range of organic pollutants, improve treatment efficiency, and maintain stability under varying conditions. The inherent diversity and interactions within the consortium contribute to a more comprehensive enzymatic activity spectrum and increased resilience in wastewater treatment processes.

The addition of oxygen can benefit the microorganisms within the consortium by providing a more favourable environment for their growth and metabolism. Oxygen is an essential component for aerobic microorganisms that require it for their respiratory processes.

When using microbial consortia in wastewater treatment, it is not necessary to worry about long-term exposure or high concentrations having a negative impact on the microbial community. Microbial consortia are specifically formulated and selected to be compatible with wastewater environments and the existing microbial populations. They are designed to enhance the overall treatment process without causing harm to the aerobic microorganisms.

DRYLET microbial consortia are designed to enhance wastewater treatment processes without causing harm to aerobic microorganisms already present in the water. These consortia are formulated to be compatible with the existing microbial community and promote overall treatment efficiency, providing a safe and effective solution for wastewater treatment applications.

Superior advantages combining Ultra-Oxygen micro and ultrafine bubble aeration with DRYLET microbial consortia biocatalyst.

In AQUACULTURE:

By combining Ultra-Oxygen micro and ultrafine bubble aeration with DRYLET microbial consortia biocatalyst, aquaculture systems experience a wide range of benefits, including improved oxygenation, accelerated waste decomposition, enhanced water quality, reduced energy consumption, minimized chemical usage, optimized water utilization, and increased system resilience. This powerful combination creates a sustainable and efficient aquaculture environment that promotes fish and plant health, ensures food security, and minimizes the ecological impact of traditional aquaculture practices.

In HYDROPONICS:

By combining Ultra-Oxygen micro and ultrafine bubble aeration with DRYLET microbial consortia biocatalyst in hydroponics farming, numerous benefits are unlocked. These include improved oxygenation and nutrient uptake, expanded microbial activity, enhanced root health, stable water quality, reduced energy consumption, minimized chemical usage, efficient water utilization, increased crop yield, and reduced environmental impact. This innovative approach fosters a more sustainable and productive hydroponics system, promoting healthy plant growth, maximizing resource efficiency, and minimizing the ecological footprint of traditional hydroponics practices.

In AQUAPONICS:

By combining Ultra-Oxygen micro and ultrafine bubble aeration with DRYLET microbial consortia biocatalyst in closed-system aquaponics, an array of benefits can be achieved. These include improved oxygenation, enhanced nutrient cycling and waste decomposition, expanded microbial activity, improved water quality and circulation, reduced energy consumption, minimized chemical usage, efficient water utilization, enhanced fish and plant health, increased system resilience, ensured food security, and reduced environmental impact. This powerful combination offers a sustainable and efficient closed-system aquaponics environment, fostering a balanced ecosystem where fish and plants thrive symbiotically while promoting self-sufficiency and environmental stewardship.

In WASTEWATER:

By combining Ultra-Oxygen micro and ultrafine bubble aeration with DRYLET microbial consortia biocatalyst in wastewater treatment, a range of benefits can be achieved. These include improved oxygenation, accelerated waste decomposition and nutrient conversion, expanded microbial activity, enhanced odour control, increased nutrient removal and pollutant reduction, reduced energy consumption, minimized chemical usage, improved water quality, efficient sludge management, reduced environmental impact, and improved overall sustainability of the wastewater treatment process. This innovative approach revolutionizes wastewater treatment, promoting efficient resource utilization, minimizing pollution, and contributing to a healthier and more sustainable environment.

Reducing COD:

By combining Ultra-Oxygen micro and ultrafine bubble aeration with DRYLET microbial consortia biocatalyst in COD reduction processes, various benefits can be achieved. These include improved oxygenation, enhanced COD reduction and breakdown of organic compounds, expanded microbial consortia with a broader enzymatic activity spectrum, improved biodegradability of complex organic compounds, reduced energy consumption, minimized chemical usage, improved water quality, efficient sludge management, reduced environmental impact, improved resource efficiency by utilizing organic waste resources, and enhanced overall sustainability. This advanced approach to COD reduction promotes effective waste management, reduces pollution, and contributes to a more sustainable and environmentally friendly process.

In BIO-REMEDIATION:

By combining Ultra-Oxygen micro and ultrafine bubble aeration with DRYLET microbial consortia biocatalyst in bio-remediation processes, several benefits can be achieved. These include improved oxygenation, enhanced bio-remediation and accelerated breakdown of contaminants, expanded microbial consortia with a broader enzymatic activity spectrum, improved breakdown of diverse contaminants and pollutants, reduced energy consumption, minimized chemical usage, improved water quality, enhanced soil remediation and increased nutrient availability, reduced environmental impact, improved resource efficiency through effective utilization of natural resources, and enhanced overall sustainability.

This innovative approach to bioremediation promotes efficient and effective treatment of contaminated sites, reduces pollution, and contributes to a more sustainable and environmentally friendly remediation process.

Solutions offered.

At the heart of our achievements lies a dedication to understanding, facilitating solutions, and resolving challenges through thoughtful inquiry.

Irrespective of the scale of your venture – whether you’re a cherished local establishment or a sprawling global enterprise – we possess the capability and sincere commitment to harmonize our strategies with your organizational ethos and aspirations. Collaboratively, we can cultivate a seamless partnership that propels your business towards unparalleled accomplishments.

Every obstacle presented before us is an opportunity to exhibit our prowess, as we approach each endeavour with an individualized perspective, mindful of its distinct contextual factors. Your project will receive the attention it deserves, embracing its unique site-specific attributes in our considerations.

“We listen, find solutions, and solve problems by asking the right questions.”

YOUR POINT OF CONTACT