Project-specific benefits are guaranteed.

Benefits available for Farms, Factories, Homes, Commercial buildings and developments, Lakes – Drinking water reservoirs – Golf Courses – Recreational Ponds – Irrigation Dams – Cooling Ponds – Water Treatment Plants – Cooling Towers

Experience the Astonishing Benefits of Micro and Ultrafine Bubbles!

In the dynamic realm of cutting-edge technology, Micro and Ultrafine bubbles have emerged as nothing short of marvels, boasting a spectrum of invaluable properties that are set to redefine the way we interact with our world. Prepare to be captivated by a world of possibilities:

1. Sterilization Wonder: Imagine harnessing the power of Micro and Ultrafine bubbles to sterilize with unmatched precision. Through a miraculous process, these bubbles transform ordinary oxygen into a potent weapon against bacteria. The result? Bactericidal molecules like OH and O3 that ensure your surroundings are not just clean but surgically sanitized.

2. Cleaning Magic: Bid farewell to cumbersome cleaning agents! Micro and Ultrafine bubbles possess a unique talent for decomposing and siphoning off oil and fat contamination. These bubbles flirt effortlessly with the gas-liquid interface, ensuring that even the most stubborn residues vanish without a trace.

3. Bio-Activation Marvel: Dive into a realm where these remarkable bubbles venture deep into biological cells, fortifying their defenses and boosting immunity. The need for antibiotics diminishes, as Micro and Ultrafine bubbles unlock the cell’s inherent power to protect itself.

4. Growth Accelerator: Witness nature’s growth spurt! With Micro and Ultrafine bubbles in the equation, your fish, crustacea, and plants will flourish, reaching sizes that defy convention by 20 to 30 percent. It’s growth, unleashed.

5. Cell Guardian: Nature’s guardian angels at work! Oysters grown with Micro and Ultrafine bubbles don’t just survive freezing temperatures; they thrive at minus 20°C. These bubbles serve as a shield, preserving cell integrity and safeguarding against the ravages of freezing.

6. Temperature Maestro: When it comes to temperature control, Micro and Ultrafine bubbles take center stage. Whether it’s a quick chill or a rapid heat-up, they master the art of swift and effective heat transfer like no other.

7. Vaporization Enigma: Unlock the secret to supercharged vaporization! These bubbles are your allies in promoting the efficient vaporization of liquids. Think water-cooled cooling towers and futuristic evaporation-based desalination systems – all made possible by the extraordinary effects of Micro and Ultrafine bubbles.

8. Environmental Saviors: Restoring balance to aquatic ecosystems, eradicating odors, and neutralizing toxic substances – the Micro and Ultrafine bubbles are nature’s champions. From lakes and rivers to vast oceans, their environmental purification capabilities endure, breathing life into our planet’s vital water bodies.

Don’t Miss Out on the Future!

Join the revolution. Embrace the exceptional capabilities of Micro and Ultrafine bubbles and redefine what’s possible in sterilization, cleaning, bio-activation, growth, temperature control, vaporization, and environmental preservation. It’s time to experience the future, today!

Contact Us to Dive into a World of Marvels!

General Observation

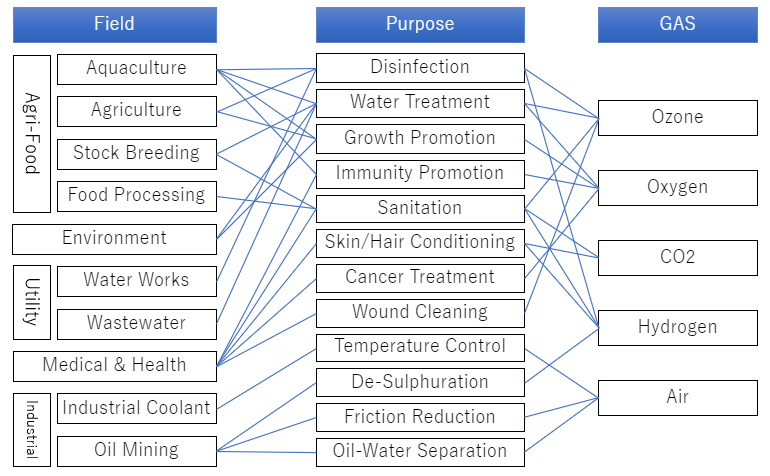

Micro and Ultrafine bubble water perform differently depending on the choice of gas to infuse it with.

Therefore, there are a lot of applications.

Benefits of using Ultra-OXYGEN Micro and Ultrafine bubble technology

Major benefits users recorded, studies verified, and results obtained from our equipment.

- Eliminate up to 70% to 90% of the current algae.

- 50% chlorophyll reduction

- 80% to 100% Copper Sulfate Reduction

- Prevent the occurrence of toxic blue-green algae.

- Increase agriculture productivity.

- Control fouling in sand filters and clarifiers.

- Prevent biofouling growth.

- Safe for fish, plants, and other aquatic life

- Reduce and prevent taste and odour problems.

- Improve water quality, and reduce pH, TSS, BOD and chemical dosage.

- Prevent clogging of filters.

- Improve coagulation and flocculation processes.

- Reduce the risk of spreading legionella.

- Improve habitat for fish and wildlife and increase Aesthetic Appearances.

- Lower bacterial counts.

- Reduce chemical expenses.

- Quality of crops

- Health of all species that live in water.

- Healthier environment.

- Humans’ well-being.