Elevate Flotation Efficiency: Ultra-Oxygen Technology for Enhanced Collision, Flexibility, and Chemical Efficiency

In the intricate world of wastewater treatment, flotation is a critical process. Ensuring efficient collision, precise control over rise rates, and optimizing chemical usage are paramount. Traditional methods may fall short, but fear not—Ultra-Oxygen MB/UFB technology is here to revolutionize your wastewater treatment.

The Flotation Challenge:

Flotation is a delicate dance that depends on several factors:

- Collision Control: Achieving effective collision between bubbles and suspended matter is crucial for efficient flotation.

- Rise Rate Precision: Tailoring the size and rise rate of bubbles to match specific wastewater conditions can be challenging.

- Chemical Optimization: Coagulants and flocculants are often necessary, but minimizing their usage is key to sustainable wastewater treatment.

The Ultra-Oxygen Solution:

Ultra-Oxygen technology offers a trifecta of advantages for flotation:

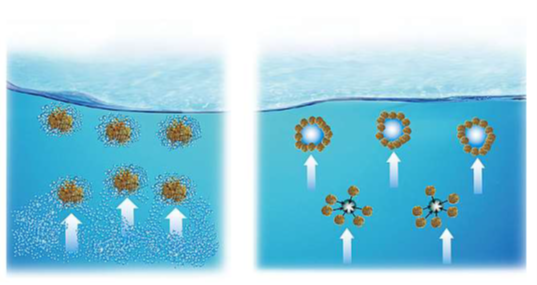

- Enhanced Collision: Negative surface charges on Micro and Ultra-Fine Bubbles (MB/UFB) prevent coalescence, increasing the likelihood of collisions with suspended matter. This translates to improved floatation rates and cleaner wastewater.

- Rise Rate Flexibility: Our technology allows operators to fine-tune the gas flow rate, enabling precise control over bubble size and rise rates. It’s a groundbreaking approach that adapts to site conditions, ensuring optimal performance in a dynamic environment.

- Chemical Efficiency: Ultra-Oxygen technology supercharges the flotation process by boosting collision rates and enhancing floc formation. This reduces the reliance on chemicals, making your wastewater treatment not only more efficient but also more sustainable.

Experience Flotation Redefined:

With Ultra-Oxygen MB/UFB technology, you can bid farewell to the limitations of traditional flotation methods. Achieve enhanced collision, rise rate flexibility, and chemical efficiency, all in one revolutionary package.

Contact Us to Revolutionize Your Wastewater Treatment and Harness the Power of Ultra-Oxygen Technology Today!